What is IP69K? A Beginner’s Guide

The IP69K rating means a piece of equipment can withstand intensive cleaning with high-pressure, high-temperature jets. IP69K products are ideal for industries where sanitation is a primary concern, such as food processing and pharmaceutical applications.

What Is IP69K?

IP69K is currently the highest rating on the ingress protection (IP) scale. The IP scale is an international system that gives products a rating based on their ability to withstand the intrusion of solids and liquids.

The first number of the rating indicates how dustproof a product is, ranging from 0 to 6. The second number indicates how watertight a product is, ranging from 0 to 9. The addition of a ‘K’ after the second digit signifies specific protection from high-pressure jets. These ratings allow a company to choose equipment with the right level of protection for a given environment.

IP69K means a product is completely dustproof and can withstand washdown at pressures of 80 to 100 bar/1,160 to 1,450 PSI, in phases of 14 to 16 l/min, and at temperatures up to 176°F/80°C.

In practice, that means high-pressure jets blasting hot water at a piece of industrial equipment with no negative consequences — an impressive achievement!

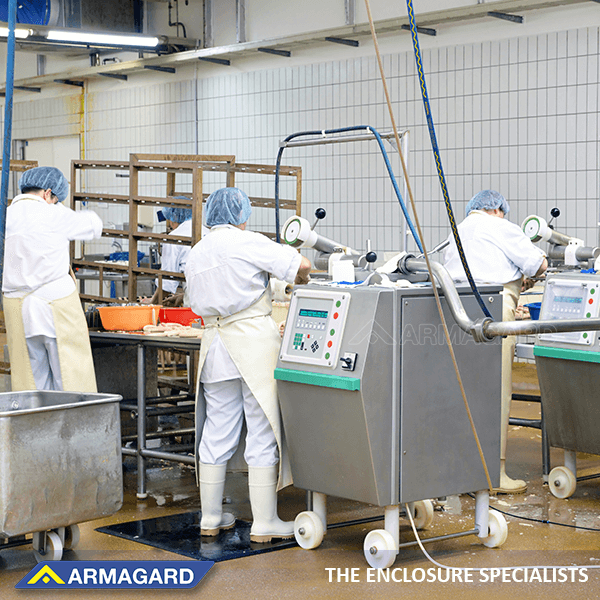

IP69K products, like KPI screen enclosures, are ideal for facilities that use intensive washdown procedures to meet strict sanitation standards:

- Food and beverage processing

- Pharmaceutical applications

- Chemical manufacturing

- Petrochemical plants

- Waste treatment

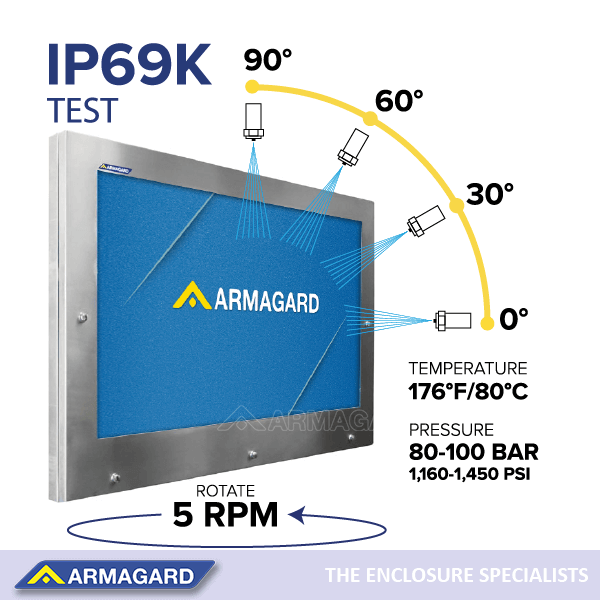

How Is IP69K Tested?

To achieve the IP69K rating, a piece of equipment must go through a rigorous water intrusion test.

The product is placed on a turntable that rotates five times a minute. It’s sprayed at 80 to 100 bar/1,160 to 1,450 PSI, in phases of 14 to 16 l/min, and at temperatures up to 176°F/80°C. The nozzle must be within four to six inches from the product, and the spray must be directed from four different angles (0°, 30°, 60°, and 90°) for 30 seconds at a time.

The product is given the IP69K rating if it completely resists water ingress under these conditions.

What Are The Benefits Of IP69K Equipment?

The IP69K test gives users confidence that a piece of equipment will hold up under intensive daily cleaning. This has several benefits:

1. IP69K Helps Manufacturers Meet Sanitation Standards

The U.S. Food & Drug Administration reports that about 48 million people in the U.S. (one in six) get sick every year from foodborne diseases.1 In response, the Food Safety Modernization Act sets out stringent regulations aimed at preventing contamination at all stages of the supply chain.

IP69K equipment helps food and pharmaceutical manufacturers meet these ever-stricter standards. IP69K products are easy to clean with high-pressure jets, which blast away debris, and the high temperature provides extra reassurance that the product is disinfected.

Many IP69K products, like shop-floor display board enclosures, are made from food-grade (316) stainless steel. This material is corrosion resistant and antibacterial, giving manufacturers further confidence in the hygiene of their plant.

This peace of mind goes beyond the formal regulations. Any contamination traced back to a facility will have a huge impact on a manufacturer’s reputation — and profits. No manufacturer wants to go through the nightmare of recalling products and pausing production, which is why IP69K equipment is increasingly popular in food and beverage processing.

2. IP69K Products Can Reduce Downtime

IP69K products are extremely reliably in harsh conditions. This means greater confidence that production can continue 24/7, without interruption.

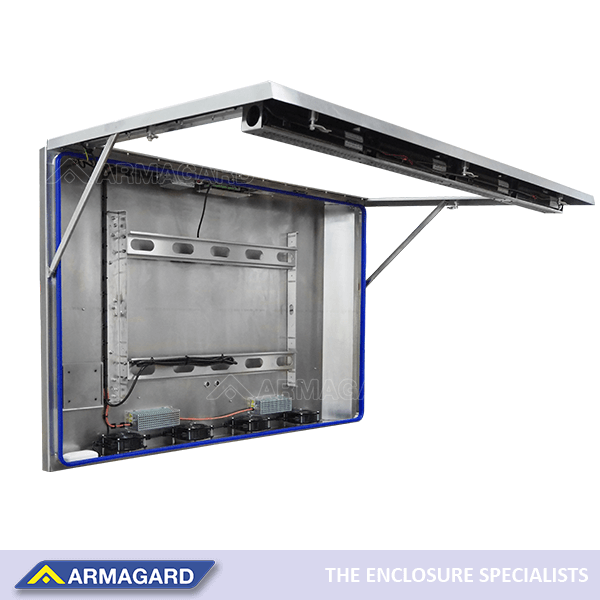

IP69K enclosures also let manufacturers use the equipment of their choice. For instance, an IP69K hygienic TV enclosure can house virtually any VESA-compatible screen of a given size. Easy access to the screen allows users to remove, repair, and replace the display at any time — without waiting for a specialist engineer. This means faster repairs and maximum uptime.

3. IP69K Products Can Boost Productivity

The IP69K rating allows manufacturers to install electrical products in virtually any harsh location. Equipment can be positioned exactly where operators need it, which improves workflow and saves time.

For example, stainless-steel computer enclosures allow workers to use PCs directly on the shop floor, without wasting time walking to an office. Similarly, IP69K display enclosures allow plants to install KPI screens in washdown areas. These displays improve factory-floor communication and give workers up-to-the-minute metrics that help them meet their targets.

An Introduction To IP69K Screen Enclosures

One popular application of the IP69K rating is stainless-steel enclosures for LCD/LED screens. These enclosures have several features that make them ideal for washdown locations:

- A completely watertight system: Hygiene-rated seals, stainless-steel cable glands, and IP69K locks guarantee a watertight unit that maximizes the lifespan of the screen.

- Climate controls: Internal fans and heaters ensure the screen operates efficiently and reliably when the ambient temperature ranges from -22°F to 86°F.

- Multiple mounting options: Ceiling or wall mounting, using flat or tilted wall brackets, allows users to position a screen in the optimum location above a production line.

- VESA compatibility: Manufacturers can install the VESA-mountable screen of their choice, from virtually any manufacturer.

- Shatterproof window: In the unlikely event of a breakage, the polycarbonate window prevents contamination by not shattering into tiny pieces.

- Expected 10-year lifespan: The same TV enclosure can protect multiple screens over several years, making it a highly cost-effective investment.

Washdown TV enclosures allow manufacturers to install KPI screens in any harsh location. Operators benefit from an improved workflow, and the IP69K rating helps plants meet strict sanitation standards.

What Is IP69K? Conclusion

The IP69K rating gives manufacturers the confidence to install electrical equipment in intensive washdown locations. Businesses benefit from improved plant hygiene, increased productivity, and reduced downtime.

For these reasons, IP69K has become the gold standard for equipment protection in food processing, pharmaceutical applications, and more.

Contact Armagard to discuss IP69K enclosures for your manufacturing floor. Call +1-866-434-0807 for a no obligation chat, or fill in a contact form to request more information.

1 www.fda.gov

This post was written by Ben Telford

As Armagard’s head of content, Ben oversees the production of articles, web copy, guest blogs and more. He aims to make Armagard’s expertise in digital screen protection accessible to customers so they can choose the right solutions for them.

Find Ben on LinkedIn.